NLGI HPM Grease and GC-LB Specifications

The NLGI HPM Grease

specification published in 2020 is big news in the grease industry1,2.

The High-Performance Multiuse (HPM) Grease specification is unique among

specifications in several ways. First, there are simply not that many

industry-wide specifications for grease2. Instead, according to

grease experts Joe Kaperick and Chuck Coe, OEMs and others with specific

lubrication needs have worked with grease manufacturers to identify or design

the grease that meets those needs3. Historically this has made

standardization difficult, though the GC-LB specification for automotive

wheel-bearing and chassis applications has been popular since its release in

the late 1980s. While the HPM Grease specification cannot meet every unique

application, it indicates a grease that will excel in most situations and even

has specific subcategories to indicate a grease’s ability to handle

particularly challenging environments such as water resistance (WR), saltwater

corrosion resistance (CR), high load carrying capacity (HL), and low

temperature performance (LT). Adding performance requirements to a core

set of requirements is a new way in setting grease specifications. Savant

Labs has stayed attuned while these developments were underway and has been

ready to offer testing to these additional requirements since the specification

was first launched. Because HPM is a high-performance specification for

multiple uses, it is more directed at industrial applications than the

particular needs of automotive applications. Grease manufacturers are

interested in demonstrating their products meet the NLGI HPM Grease

specification because it indicates a very good grease formulation for most

applications, especially with the added enhanced performance requirements.

The NLGI HPM Grease

specification published in 2020 is big news in the grease industry1,2.

The High-Performance Multiuse (HPM) Grease specification is unique among

specifications in several ways. First, there are simply not that many

industry-wide specifications for grease2. Instead, according to

grease experts Joe Kaperick and Chuck Coe, OEMs and others with specific

lubrication needs have worked with grease manufacturers to identify or design

the grease that meets those needs3. Historically this has made

standardization difficult, though the GC-LB specification for automotive

wheel-bearing and chassis applications has been popular since its release in

the late 1980s. While the HPM Grease specification cannot meet every unique

application, it indicates a grease that will excel in most situations and even

has specific subcategories to indicate a grease’s ability to handle

particularly challenging environments such as water resistance (WR), saltwater

corrosion resistance (CR), high load carrying capacity (HL), and low

temperature performance (LT). Adding performance requirements to a core

set of requirements is a new way in setting grease specifications. Savant

Labs has stayed attuned while these developments were underway and has been

ready to offer testing to these additional requirements since the specification

was first launched. Because HPM is a high-performance specification for

multiple uses, it is more directed at industrial applications than the

particular needs of automotive applications. Grease manufacturers are

interested in demonstrating their products meet the NLGI HPM Grease

specification because it indicates a very good grease formulation for most

applications, especially with the added enhanced performance requirements.

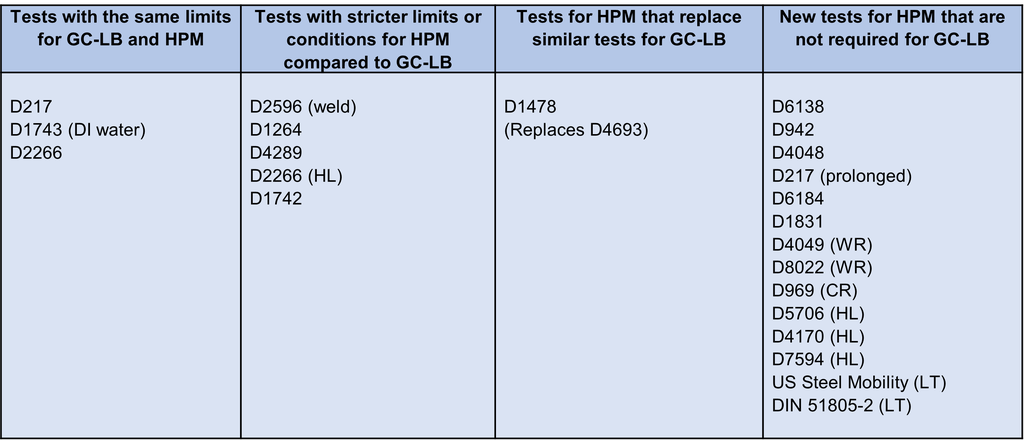

NLGI HPM vs. GC-LB Testing Requirements

The requirements for the HPM specification can

most easily be classified in comparison to those for the previous automotive

specification GC-LB. It’s interesting to note that many of the testing

requirements to obtain an HPM specification are similar to those for the

historical GC-LB specification1, and Savant Labs can offer testing for both.

The worked-60 penetration test (ASTM D217), the bearing rust with DI water test

(ASTM D1743), and the four-ball wear test (ASTM D2266) are implemented with the

same limits. The four-ball extreme pressure test (ASTM D2596), the water

washout test (ASTM D1264) and the oil separation test over 24 hours at 25 °C

(ASTM D1742), are the same tests with stricter limits, while the acrylonitrile

butadiene rubber (NBR) hardness and volume change test (ASTM D4289) uses

harsher conditions with identical limits and a new elastomer material.

The low temperature torque test at -40 °C (ASTM D4693) has been replaced

by the low temperature torque ball bearing test at –20 °C (ASTM D1478) with

limits for starting and running torque. There are also new tests required for

the HPM core specification: the Emcor rust test with distilled water (ASTM

D6138), oxidation stability (ASTM D942), copper corrosion (ASTM D4048),

prolonged worked penetration (ASTM D217), high temperature bleed (ASTM D6184),

and roll stability (ASTM D1831).

More stringent limits or additional tests are

required for the enhanced performance requirements. To gain the water

resistance tag, the water washout test (ASTM D1264) limits are more stringent.

Additionally, the water spray off test (ASTM D4049) and wet roll stability test

(ASTM D8022) are required. Corrosion resistance requires the bearing rust test

with 10% simulated seawater (ASTM D5969) and the Emcor rust test with both

simulated seawater and a 0.5 N NaCl solution (ASTM D6138). The high load tag

requires increased limits for four-ball wear (ASTM D2266) and four-ball extreme

pressure (ASTM D2596). It also requires the SRV step load test, Procedure B at

80 °C (ASTM D5706), fretting wear loss (ASTM D4170), and fretting wear scar by

SRV (ASTM D7594). The low temperature tag requires the low temperature torque

ball bearing test at –30 °C (ASTM D1478), the US Steel Mobility test at -20 °C,

and a low temperature flow test at -30 °C (DIN 51805-2).

Table 1. Tests for HPM compared to GC-LB3. DXXXX represents an ASTM test method.

For a complete comparision visit NLGI's HPM vs. GC-LB Comparsion chart.

Additional Applications for Grease Testing

The HPM specification is designed with

industrial applications in mind. If a grease does not have the specification,

it is a simple matter to complete testing to the standards to see how it

compares to an HPM certified grease. However, there may be specific

instances where even more testing is desirable.

The HPM specification is designed with

industrial applications in mind. If a grease does not have the specification,

it is a simple matter to complete testing to the standards to see how it

compares to an HPM certified grease. However, there may be specific

instances where even more testing is desirable.

Modified wear protection testing is another

common extra for greases. While the HPM-HL specification provides

assurance of the ability to carry a high load, wear can occur over a wide range

of load, speed, and temperature conditions. SRV testing can be customized

beyond the limits and conditions specified for HPM-HL to address any specific

need for a particular application. Savant Labs has a great deal of experience

doing custom testing for these situations. Other common applications include

compatibility testing and in-service testing, both of which Savant Labs can

provide.

By far the most common reasons for grease

testing are to meet NLGI HPM or GC-LB specifications, to answer questions about

suitability of a grease for a particular application, or to assess the health

of the system with in-service testing. However, testing is also done to

meet the handful of other specifications, such as railroad standards EN1208,

AAR M-914, and M0949 or various OEM specifications4.

Complete

Grease Specification Testing Services

Whatever the grease testing need may be, Savant

Labs can provide excellent service to address it. We offer a complete line of

grease specification testing services, including a specific package to address

HPM certification with or without tags. We also have extensive experience

with compatibility testing using ASTM D6185 and custom tests. We

provide standardized SRV wear testing to ASTM D5706 and D7594 as well and a

wide range of customized temperatures, loads, and speeds.

For the full range of standardized grease tests

Savant Labs offers please see the test list on our website. Because Savant Labs is most well-known for our

ability to complete custom testing for special projects that address the

fundamental concerns of our customers, we are confident we can also assist with

any novel grease problem. The necessary and critical first step is to contact Savant Labs, to see

how we can help with your company’s grease testing needs.

- Sosa, Yulia. (2021, September). “New and in-service grease testing.” Tribology & Lubrication Technology, 77 (9), pp. 38-48. https://www.stle.org/files/TLTArchives/2021/09_September/Cover_Story.aspx

- Mistry, Anuj. (2021, October). “NLGI specifications meet special needs.” Efficient Plant, 34 (8), p. 25. https://www.nxtbook.com/atp/MaintenanceTechnology/efficient-plant-october-2021/index.php#/p/24

- NLGI Official.(2021, April 13). HPM Certification [Video]. YouTube. https://www.youtube.com/watch?v=O4VFbSjWHkA

- Coe, Chuck. (2022, May/June). “The danger of cross reference

charts.” Plant engineering, 76 (3), pp. 37 – 38 https://bt.e-ditionsbyfry.com/publication/?m=32190&i=750491&p=39&ver=html5