Industrial Lubricant/Gear Oil Testing Capabilities

It should come as no surprise that

gear oil is a huge industry. Gears are among the most ubiquitous mechanical

components of our commercial manufacturing and distribution systems, and every

gear needs lubrication. According to Infineum’s estimation in 2018, the global

demand for all gear lubrication came to about 2,400 kT/yr, with about 40% of

that demand for industrial gear oil and the rest for automotive gear oil. Of

the 15% of demand in the North American market, about 60% was for industrial

gear oil. [1] DataM Intelligence estimates a 2.6% annual growth rate in the

gear oil market [2], so current demand may be as high as 2,700 kT/yr. Gear oil

is big business, and lubricant manufacturers must keep up with end users’ needs

to be competitive.

It should come as no surprise that

gear oil is a huge industry. Gears are among the most ubiquitous mechanical

components of our commercial manufacturing and distribution systems, and every

gear needs lubrication. According to Infineum’s estimation in 2018, the global

demand for all gear lubrication came to about 2,400 kT/yr, with about 40% of

that demand for industrial gear oil and the rest for automotive gear oil. Of

the 15% of demand in the North American market, about 60% was for industrial

gear oil. [1] DataM Intelligence estimates a 2.6% annual growth rate in the

gear oil market [2], so current demand may be as high as 2,700 kT/yr. Gear oil

is big business, and lubricant manufacturers must keep up with end users’ needs

to be competitive.

Applications of Gear Oils

The

differences between industrial and automotive gear oils and specific gear oils

within either category depend on the particular application. [1,3] Savant Labs’

customers cover a wide range of applications. Gears requiring lubrication are

ubiquitous in warehouses and logistic centers focusing on product distribution.

Industrial manufacturing also uses gear-driven equipment, from automotive

assembly lines to automated manufacturing. Gears are also present in energy

generation systems. The most significant use of gear oils in energy generation

may be the myriad of wind turbines providing sustainable electricity.

Finally, automotive gear oils form a large portion of the industry. Every

vehicle with a manual transmission, whether a passenger car or a heavy-duty commercial

truck, uses automotive gear oil. Many early electric vehicles also used gear

oils for lubrication until it became evident that EVs have special lubrication

needs. Nonetheless, EV lubricants still share a number of properties with

automotive gear oils.

The

differences between industrial and automotive gear oils and specific gear oils

within either category depend on the particular application. [1,3] Savant Labs’

customers cover a wide range of applications. Gears requiring lubrication are

ubiquitous in warehouses and logistic centers focusing on product distribution.

Industrial manufacturing also uses gear-driven equipment, from automotive

assembly lines to automated manufacturing. Gears are also present in energy

generation systems. The most significant use of gear oils in energy generation

may be the myriad of wind turbines providing sustainable electricity.

Finally, automotive gear oils form a large portion of the industry. Every

vehicle with a manual transmission, whether a passenger car or a heavy-duty commercial

truck, uses automotive gear oil. Many early electric vehicles also used gear

oils for lubrication until it became evident that EVs have special lubrication

needs. Nonetheless, EV lubricants still share a number of properties with

automotive gear oils.Application-Specific Functions

To understand why many needs are application-specific, consider oxidation resistance. This property is most important in applications that generate heat, such as high-speed gears, gears with high friction or sliding, or automotive applications near a heat-generating internal combustion engine. The need for viscosity stability across different temperature ranges and cold-temperature operation also depends on the application. Therefore, in contrast to an indoor application, wind, and automotive applications usually require multi-grade oils and good low-temperature performance.

Changing Needs for Gear Oils

The need for

protection has become more challenging as gearbox designs have continued to

advance. Smaller gearboxes with increased power and less sump volume

require lubricants with improved anti-wear or extreme pressure protection,

better oxidation resistance, and better resistance to foaming. As new

materials are used to make gears, some base oils or additives may react with

these new materials, and it becomes critical to verify compatibility. Finally,

as users seek to reduce costs and improve environmental sustainability, longer

drain intervals become desirable, and certain additives, such as those

containing zinc, phosphorous, and sulfur, become less desirable. Extended use

requires lubricants with excellent oxidative, thermal, and viscosity stability

as well as the ability to reject contaminants such as water. [3]

Whether it be anti-wear, extreme pressure protection, oxidation resistance,

resistance to foaming, thermal or viscosity stability, and more, a complete

listing of gear lubricant

testing services

is available.

Gear Oil Specifications

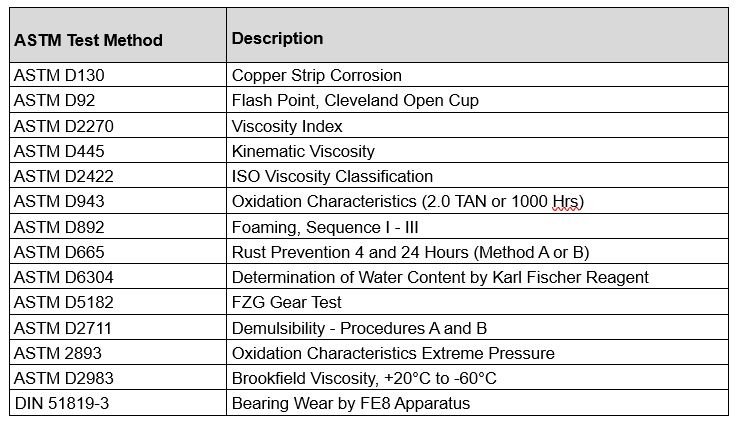

With so many general and specific requirements, gear oil standards play an important role in ensuring that a given lubricant can meet the consumer’s needs. Typically, industrial gear oils meet a baseline standard dependent on region. For instance, AGMA 9005 is specific to North America, DIN 51517-3 to Europe, and SEBI 181 226 to Germany. [1, 3, 4] These regional standards include testing for corrosiveness, flash point, viscosity index, water content, foaming, water separation, load capacity, bearing wear, oxidation, and low-temperature viscosity, as shown in Table 1. OEMs often supplement these specifications with additional requirements. [1,4] Automotive gear oils have their own viscosity classification and performance standards, SAE J306 and SAE J2360. These include many of the same tests as the North American AGMA specification as well as shear stability, seal compatibility, and some specialized tests for oxidation stability, thermal stability, and performance with gears. [1]Table 1. Tests required to meet AGMA 9005 [5,1]

Condition Monitoring of Gear Oils

In addition to testing to meet specifications, condition monitoring of in-service lubricants can be an excellent preventative maintenance and drain-interval extension technique. Periodically testing the fluid can give important indicators about the state of the gears. Changes in lubricant viscosity and makeup can indicate critical changes in the system. For instance, viscosity is known to increase as oil oxidizes. A reduction in viscosity could indicate permanent shear loss or contamination in the system that could cause serious damage if left unaddressed. A change in the metallic components found by elemental analysis (ASTM D5185) could indicate depletion of additives, particles of wear metals in the sample, or corrosion. In addition, it is also useful to monitor water content (ASTM D6304) and acid number through “oxidation lifetime" (ASTM D943). Increases in water content can drive corrosion and increases in acid number can indicate excessive oxidation products in the fluid. It is important to note that a successful condition monitoring program begins by testing the fresh oil to establish a baseline. [6]

Savant’s Gear Oil Testing Capabilities

Savant

offers the tests included in the AGMA 9005 specification as well as additional

specialized application- or manufacturer-specific tests. We can also:

Savant

offers the tests included in the AGMA 9005 specification as well as additional

specialized application- or manufacturer-specific tests. We can also:

- Perform the tests necessary for a successful condition monitoring program. Sometimes, there may be a specific problem with a gear-driven system or questions about whether a particular lubricant will be adequate.

- Develop custom testing and provide problem-solving efforts that can help identify lubricant-based root causes.

- Determine an array of tests that will best address a particular challenge.

- Provide expertise in new test development. We can assist in developing tests for emerging challenges faced by both manufacturers of novel gears and novel gear lubricants.

Contact

Savant Labs for a quote on

standard gear oil testing or to learn more about how our custom testing capabilities could address your

needs.

References:

[1] Infineum. “Gear Lubricants.” Infineum Insight. 2008. https://www.infineuminsight.com/media/1821/10-gear-lubricants-na.pdf, accessed July, 2023.

[2] Data Intelligence. “Gear Oil Market Size, Share, Trends, Outlook, Growth

Opportunities, and Forecast 2023 – 2030.” May 24, 2023. https://www.datamintelligence.com/research-report/gear-oil-market, accessed July, 2023.

[3] Rob Profilet. “Trends in Industrial Gear Oil,” Machinery Lubrication. Jan., 2008.

https://www.machinerylubrication.com/Read/1292/industrial-gear-oils

[4] Van Rensselar, Jean. “Gear Oils,” Tribology and Lubrication

Technology: 28 - 33. Feb., 2013 https://www.stle.org/images/pdf/STLE_ORG/BOK/OM_OA/Additives/Trends%20in%20Industrial%20Gear%20Oils_tlt%20article_Feb13.pdf

[5] American National Standard. “Industrial Gear Lubrication,” ANSI/AGMA

Standard 9005-E02, Rev. Dec., 2002.

[6] Dagnino, Jesus Teran. “Oil Analysis Interpretation for Gearboxes,”

Machinery Lubrication, Aug., 2021. https://www.machinerylubrication.com/Read/32068/oil-analysis-interpretation-gearboxes