Electric Driveline Fluid Testing Update June 2023

Conductive Deposit Test (CDT)

and Wire Corrosion Test (WCT)

The automotive lubricant industry has been charged on the buzz around electric

vehicles for the last few years. In the 2021, Savant shared

news about new methods developed specifically to test fluids for

compatibility with electric vehicles and the then-in-progress SAE

document listing these tests. Last fall the awaited SAE J3200_202210

Information Report was published. As expected, it includes a discussion

of the benefits and uses of the Conductive Deposit Test (CDT) and the

Wire Corrosion Test (WCT) that Savant Labs now offers, along with several

other tests. More action regarding these tests is ongoing within

the ASTM D02 Committee. Last December the ASTM D02 Subcommittee 9 on

Oxidation of Lubricants presented plans to complete a full Interlaboratory

Study (ILS) to determine a precision statement for the Conductive Deposit

Test and make it an official ASTM Standard Test Method. The

Subcommittee also presented plans for a pilot study on the Wire Corrosion

Test to determine how many labs will need to participate in an upcoming

full ILS.

The automotive lubricant industry has been charged on the buzz around electric

vehicles for the last few years. In the 2021, Savant shared

news about new methods developed specifically to test fluids for

compatibility with electric vehicles and the then-in-progress SAE

document listing these tests. Last fall the awaited SAE J3200_202210

Information Report was published. As expected, it includes a discussion

of the benefits and uses of the Conductive Deposit Test (CDT) and the

Wire Corrosion Test (WCT) that Savant Labs now offers, along with several

other tests. More action regarding these tests is ongoing within

the ASTM D02 Committee. Last December the ASTM D02 Subcommittee 9 on

Oxidation of Lubricants presented plans to complete a full Interlaboratory

Study (ILS) to determine a precision statement for the Conductive Deposit

Test and make it an official ASTM Standard Test Method. The

Subcommittee also presented plans for a pilot study on the Wire Corrosion

Test to determine how many labs will need to participate in an upcoming

full ILS.

With industry standardization groups showing so much interest in electric

driveline fluid tests, it’s clear that they are important to the

industry. Why are they so important? In the last two years,

many lubricant manufacturers have been developing special-purpose

lubricants to meet the needs of electric vehicles. This follows a

period when axle oils, manual transmission fluids, or ATFs were used to

lubricate the electric vehicle driveline and even to provide cooling to

the electric motor. Corrosion to an electric motor exposed to a lubricant

has been known to cause catastrophic failures [1], [2], [3]. Perhaps the

recent interest in dedicated fluids results from knowledge of such

instances and the needs outlined in SAE J3200_202210. Whether producing a

lubricant tailored to the specific needs of an electric vehicle or

verifying the compatibility of a pre-existing fluid with an EV

application, it has become necessary to use tests that can reveal

critical failures, such as the CDT and WCT.

Conductive

Deposit Test The Conductive

Deposit Test is specifically designed to detect conductive deposits that

could create a short in an electric motor or other critical

circuitry. A printed circuit board with copper traces is used to

stand in for relevant copper-containing electrical components, such as

motor windings, in the electric vehicle. The circuit board is exposed to

the test fluid under controlled temperature with minimal fluid flow and

closed, but not sealed, headspace. This simulates the conditions in

EVs where components are tightly spaced and may not see much fluid

circulation or are exposed to vapors from the lubricant during normal

use. As copper from the circuit is corroded, it can combine with

components of the fluid and stick to the circuit board as deposits.

If these deposits can conduct electricity, a problem occurs when

they bridge the gap between two otherwise unconnected circuit

components. In a real-life application, this could cause unintended

currents to flow between circuit components, quickly overheating the

components, and causing deformation or even welding [3]. In the CDT, the

resistance measured on the test drops to a low value. The speed

with which this happens and the final resistance are used to infer the

suitability of a fluid for the application. Limits are currently

set by each manufacturer, but industry-wide limits may eventually be

established by standardization groups. The test may run for up to

1000 hours to build extra confidence in the long-term operation of the

fluid, but the resistances drop to concerning values in less than 500

hours for fluids with problematic results in the field. In addition, as

the deposits form, the variability of the resistance increases

dramatically due to the intermittent nature of the electrical connection formed

by the deposit. This is measured with the Conductive Deposit Index

(CDI). Either the CDI or the resistance value can be used to

identify a fluid with poor performance in the field. Both the resistance

limit indicating a failure and the Conductive Deposit Index limit

indicating a failure may be adjusted to correspond with particular

applications.

The Conductive

Deposit Test is specifically designed to detect conductive deposits that

could create a short in an electric motor or other critical

circuitry. A printed circuit board with copper traces is used to

stand in for relevant copper-containing electrical components, such as

motor windings, in the electric vehicle. The circuit board is exposed to

the test fluid under controlled temperature with minimal fluid flow and

closed, but not sealed, headspace. This simulates the conditions in

EVs where components are tightly spaced and may not see much fluid

circulation or are exposed to vapors from the lubricant during normal

use. As copper from the circuit is corroded, it can combine with

components of the fluid and stick to the circuit board as deposits.

If these deposits can conduct electricity, a problem occurs when

they bridge the gap between two otherwise unconnected circuit

components. In a real-life application, this could cause unintended

currents to flow between circuit components, quickly overheating the

components, and causing deformation or even welding [3]. In the CDT, the

resistance measured on the test drops to a low value. The speed

with which this happens and the final resistance are used to infer the

suitability of a fluid for the application. Limits are currently

set by each manufacturer, but industry-wide limits may eventually be

established by standardization groups. The test may run for up to

1000 hours to build extra confidence in the long-term operation of the

fluid, but the resistances drop to concerning values in less than 500

hours for fluids with problematic results in the field. In addition, as

the deposits form, the variability of the resistance increases

dramatically due to the intermittent nature of the electrical connection formed

by the deposit. This is measured with the Conductive Deposit Index

(CDI). Either the CDI or the resistance value can be used to

identify a fluid with poor performance in the field. Both the resistance

limit indicating a failure and the Conductive Deposit Index limit

indicating a failure may be adjusted to correspond with particular

applications.

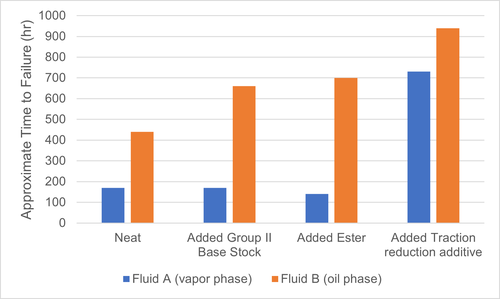

Currently, Savant has multiple customers routinely using the CDT to assess EV fluids. In addition, research efforts proceed. In a paper recently presented at the OilDoc conference, Greg Miiller of Savant Group compared failure times for two fluids with their failure times once diluted with group II base stock, an ester, and a traction reduction additive. Fluid A was considered poor performing in the vapor phase while Fluid B was considered to have poor performance in the oil phase. As can be seen in the graph below, addition of the tracking fluid greatly reduced the likelihood of conductive deposit formation for each fluid within those fluids problematic deposit forming region and outperformed the other diluents tested. Future studies are currently in the developmental stage to examine the effects of mixed lubricant systems for EV applications.

Figure 1. Summary

of dilution results for Fluid A and Fluid B.

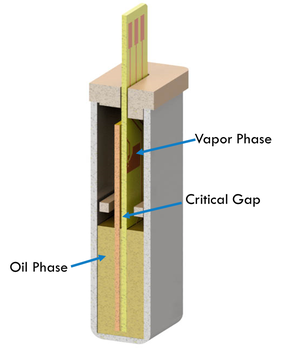

Wire

Corrosion Test  While the CDT

assesses the tendency of a fluid to create conductive deposits that can

short a circuit, the wire corrosion test quantifies the tendency of a

fluid to corrode copper. Traditional copper corrosion tests like

ASTM D130 and adaptations based on it tend to be subjective and

qualitative. The advantage of the wire corrosion test is that the

corrosion rate can actually be determined in a given sample. A thin

wire is exposed to an oil and its vapor with a separate circuit for each

phase at a controlled temperature for 72 hours. In the case of the WCT,

the wires are spaced sufficiently far apart that no deposits would be

able to bridge the gap. Furthermore, the wires are suspended so there is

no substrate on which deposits can form. As the copper is corroded the

resistance of the circuit increases. Based on the known initial

diameter and resistance of the wire, the diameter can be calculated at

any time during the test based on the resistance, and the actual rate of

corrosion can be determined. Furthermore, this test can easily be

conducted at temperatures from 80 °C to 150 °C, allowing the temperature

dependence of corrosion rates to be established for different fluids in

both the oil and vapor phases [1]. The developers of this test found that

temperature dependence varies significantly by fluid and that the hottest

temperatures may not always be the most severe, particularly in the vapor

phase [3]. These results underscore the importance of testing

changes in formulation and testing across the full range of temperatures

anticipated in the application. Savant Labs has been offering the WCT

since 2021, and multiple customers have made use of the ability to test

at several temperatures in order to fully characterize the copper

corrosion effects of various fluids. In addition, the duration of the

test can be extended to examine the corrosion rates in even very

high-performing fluids.

While the CDT

assesses the tendency of a fluid to create conductive deposits that can

short a circuit, the wire corrosion test quantifies the tendency of a

fluid to corrode copper. Traditional copper corrosion tests like

ASTM D130 and adaptations based on it tend to be subjective and

qualitative. The advantage of the wire corrosion test is that the

corrosion rate can actually be determined in a given sample. A thin

wire is exposed to an oil and its vapor with a separate circuit for each

phase at a controlled temperature for 72 hours. In the case of the WCT,

the wires are spaced sufficiently far apart that no deposits would be

able to bridge the gap. Furthermore, the wires are suspended so there is

no substrate on which deposits can form. As the copper is corroded the

resistance of the circuit increases. Based on the known initial

diameter and resistance of the wire, the diameter can be calculated at

any time during the test based on the resistance, and the actual rate of

corrosion can be determined. Furthermore, this test can easily be

conducted at temperatures from 80 °C to 150 °C, allowing the temperature

dependence of corrosion rates to be established for different fluids in

both the oil and vapor phases [1]. The developers of this test found that

temperature dependence varies significantly by fluid and that the hottest

temperatures may not always be the most severe, particularly in the vapor

phase [3]. These results underscore the importance of testing

changes in formulation and testing across the full range of temperatures

anticipated in the application. Savant Labs has been offering the WCT

since 2021, and multiple customers have made use of the ability to test

at several temperatures in order to fully characterize the copper

corrosion effects of various fluids. In addition, the duration of the

test can be extended to examine the corrosion rates in even very

high-performing fluids.

Learning

More About EV Driveline Fluid Testing

Perhaps the best way to learn more about how you might use the Conductive

Deposit Test and the Wire Corrosion Test to electrify the development of your EV

fluids is to contact us for a conversation about how Savant Labs can

adapt these tests to your specific needs.

References

[1] Miiller, Gregory; VanBergen, William; Kurchan, Alexei; Gillespie, David;

Mueller, Gunther; Pelz, Rico; Newcomb, Timothy; Hunt, Gregory, (2023, May

9 -11). Research and Development Utilizing the Conductive Layer Deposits

and Wire Corrosion Bench Test Technology for Electric Vehicle

Drivetrains, OilDoc Conference 2023, Rosenheim, Germany.

[2] Van Rensselar, Jeanna. (2022, November). “Rapidly expanding electric

vehicle market spurs lubricant development urgency.” Tribology & Lubrication

Technology, 78 (11), pp. 34-40.

[3] SAE 2020-01-0561 “Understanding Vapor and Solution Phase Corrosion of

Lubricants Used in Electrified Transmissions” Hunt, Gregory and

Prengaman, Christopher.